INDUSTRIAL SECTOR: automation and precision

Optoi manufactures high-quality industrial sensors that can be customised according to customer requirements.

The industrial division is the first of the Group to have been set up and currently constitutes its core business. It designs and manufactures two main product ranges: components and sensors for industrial automation. Optoi follows the whole supply chain vertically for both ranges, from research and development to manufacturing according to customer requirements. Every process is carried out at our premises in Trento, and only highly qualified personnel are assigned to the projects.

The industrial division is the first of the Group to have been set up and currently constitutes its core business. It designs and manufactures two main product ranges: components and sensors for industrial automation. Optoi follows the whole supply chain vertically for both ranges, from research and development to manufacturing according to customer requirements. Every process is carried out at our premises in Trento, and only highly qualified personnel are assigned to the projects.

Components and Sensors

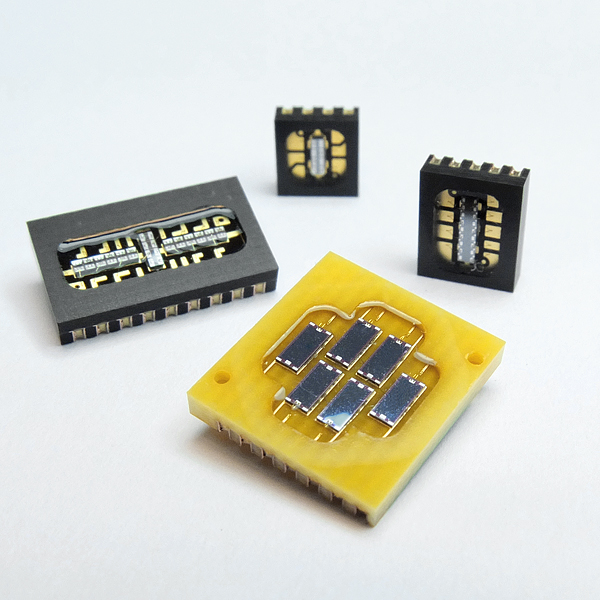

We primarily manufacture silicon photoreceivers in various shapes, sizes and packages for the industrial sector. Regarding sensors for industrial automation, we manufacture electronic circuits of varying complexity that are composed of a transducer, conditioning electronics and housing mechanics.

The close partnership with the FBK research centre also enables us to monitor the so-called front-end part of semiconductor design, production and quality control.

The close partnership with the FBK research centre also enables us to monitor the so-called front-end part of semiconductor design, production and quality control.

Industrial Division Products

Optical sensors for rotary and linear encoders

Our industrial sensors include photodiodes, phototransistors, highly sensitive detectors, LEDs, VCSELs and lasers, right up to more complex systems that form the reading head of an encoder or standard sensing elements for optical encoders. These devices can be cut and/or assembled individually or in monolithic arrays or multiplexed in arrays with a specific optical pitch.

The type of casing used can be made of plastic, metal or ceramic, depending on the performance, price and strength requirements.

The type of casing used can be made of plastic, metal or ceramic, depending on the performance, price and strength requirements.

Sensors for optical fibre industrial communications

Sensors for optical fibre industrial communications are components made with a double package suitable for inserting a plastic or glass optical fibre; we also provide emitters and receivers.

These components enable optoelectronic communication between machine control units while maintaining galvanic isolation. Therefore, they are mainly used in the railway sector and in industrial environments where high immunity to electromagnetic interference is required.

These components enable optoelectronic communication between machine control units while maintaining galvanic isolation. Therefore, they are mainly used in the railway sector and in industrial environments where high immunity to electromagnetic interference is required.

Inclination and Vibration Sensors

Inclination and vibration sensors are complex devices based on a MEMS transducer interrogated by a microcontroller, which provides a suitable output using an algorithm. Inclination sensors are used in applications that check the flatness of work machines and control the position of parts of electrical or hydraulic systems, e.g. position control in photovoltaic tracking systems. On the other hand, vibration sensors are used in applications that check wind turbines and their parts or the vibration in industrial machinery.

Level or Single Position Sensors

These optoelectronic devices are based on emitters and receivers that work on the principle of reflection/refraction. Our level sensors feature integrated smart electronics to handle transducer signals and provide reliable measurements. The most common applications are the measurement of ON/OFF levels and precise positions of mechanical parts.

Position Sensors

Position sensors are complex devices based on an optoelectronic transducer that consists of an array of photoelements and an illuminator. Working in reflection on a barcode, these elements measure the absolute position of the object on which the code is deposited.

The sensors measure mechanical parts of machinery directly on the object whose position needs to be known. They also feature a microcontroller that manages the measurement, processes the data, applies algorithms and any additional controls required for measuring reliability and handles the most suitable type of output for the end-user.

The sensors measure mechanical parts of machinery directly on the object whose position needs to be known. They also feature a microcontroller that manages the measurement, processes the data, applies algorithms and any additional controls required for measuring reliability and handles the most suitable type of output for the end-user.

Tests and checks, a guarantee of quality

Our constant commitment to quality is reflected in our rigorous raw material inspection procedures and in-line tests. Final tests are performed on every product, first at the semiconductor/slice level and then on the completed device before packaging and shipping to the customer.

The company uses the best and most modern design techniques, carries out material analyses, generates studies on the reliability and robustness of the components, develops intelligent algorithms and promotes a high degree of responsibility among technical personnel.

All Optoi activities are governed by a quality system certified according to ISO 9001:2015 Standards.

The company uses the best and most modern design techniques, carries out material analyses, generates studies on the reliability and robustness of the components, develops intelligent algorithms and promotes a high degree of responsibility among technical personnel.

All Optoi activities are governed by a quality system certified according to ISO 9001:2015 Standards.