MOBILITY SECTOR: sensors for patented cylinders.

The mobility division specialises in manufacturing innovative, patented cylinder sensors that are immune to electromagnetic fields, integrated and tamper-proof, resistant to external influences and, above all, suitable for all types of cylinders.

Reliability and Robustness are the foundation of the design of these intelligent microsystems.

Reliability and Robustness are the foundation of the design of these intelligent microsystems.

Advanced technology, durability, versatility

The mobility division originated twenty years ago following the first groundbreaking project aimed at providing hydraulic cylinders with sensors. This application allowed the detection of the cylinder's centre position using an intelligent optoelectronic reflective sensor. Our first position sensor was introduced onto the market in 2005; since then, the Group has been a pioneer in optical sensors applied to hydraulic cylinders. During the past 15 years, our single position sensor has sold more than 700,000 units with an extremely low failure rate (at automotive levels).

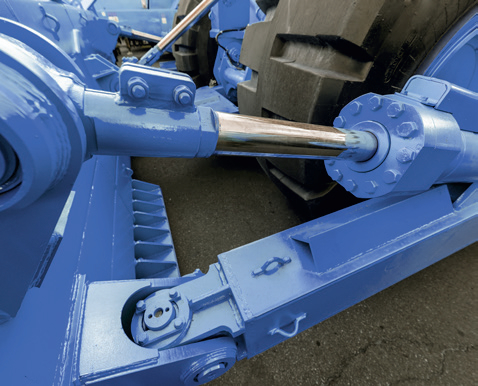

In collaboration with Giuliani Cilindri, Optoi has developed highly reliable technology that allows the position of a rod to be measured at single points or continuously. This measurement is read through the emission and reception of an optical beam reflected by the specially marked rod through laser ablation techniques. This technology, protected by multiple patents across all continents, offers several benefits.

It is, in fact:

In collaboration with Giuliani Cilindri, Optoi has developed highly reliable technology that allows the position of a rod to be measured at single points or continuously. This measurement is read through the emission and reception of an optical beam reflected by the specially marked rod through laser ablation techniques. This technology, protected by multiple patents across all continents, offers several benefits.

It is, in fact:

- unaffected by external electromagnetic fields

- fully integrated and highly tamper-proof

- protected against environmental conditions such as humidity, dust, or mud

- suitable for all types of cylinders

Mobility Division Products

Single Position Sensors

Single position sensors are simple devices based on an optoelectronic transducer that consists of an emitter and a receiver. Working in reflection on a non-contact reflective surface, when they detect colour discontinuity, they associate it with a specific position of the object. These elements are typically applied to hydraulic cylinders and control the rod surface. Furthermore, they have a long life cycle as they have a microcontroller with a dedicated algorithm that can detect wear over time and adapt to it.

Single position sensors can measure a single or a few positions; they are available in various versions, even with diagnostics and redundancy for critical applications.

Single position sensors can measure a single or a few positions; they are available in various versions, even with diagnostics and redundancy for critical applications.

Absolute Position Sensors

Absolute position sensors are devices based on an optoelectronic transducer that consists of an array of photoelements and an illuminator. Working in reflection on a barcode, they measure the absolute position of the object on which the code is deposited.

These elements are applied to hydraulic cylinders and control the rod surface. Furthermore, they have a long life cycle as they feature a microcontroller with a dedicated algorithm that can detect wear over time and adapt to it.

Thanks to their patented coding, they can measure the absolute position, i.e. they do not need zero to start reading.

These elements are applied to hydraulic cylinders and control the rod surface. Furthermore, they have a long life cycle as they feature a microcontroller with a dedicated algorithm that can detect wear over time and adapt to it.

Thanks to their patented coding, they can measure the absolute position, i.e. they do not need zero to start reading.

Inclination Sensors

Inclination sensors are complex devices based on a MEMS transducer interrogated by a microcontroller, which provides a suitable output using an algorithm. Inclinometers are used to monitor flatness and stability. These are essential for ensuring personnel safety, particularly on industrial machines such as aerial platforms, fruit picking platforms, forklift trucks, and any vehicle requiring control of various mechanical components that can be tilted, rotated, or extended.

The inclination sensors are available in various versions with 1 or 2 axes, a digital or analogue output, a relay option, simple or redundant, etc.

The inclination sensors are available in various versions with 1 or 2 axes, a digital or analogue output, a relay option, simple or redundant, etc.

Level Sensors

Level sensors are optoelectronic devices based on emitters and receivers that work on the principle of reflection and refraction. These elements feature integrated smart electronics to handle transducer signals and provide reliable measurements. Frequent applications are to measure ON/OFF levels in tanks containing oil, water and any other liquid.